LED Lights are in huge demand all over the market whether it’s your home or workplace. Talking particularly about the workplace, there are several industries with different kinds of light requirements.

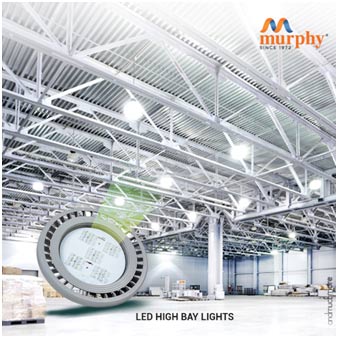

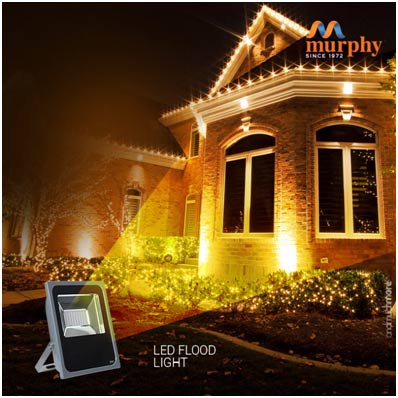

No matter which field you belong to, light is used everywhere. But the question is whether you should be using the conventional high intensity luminaries or switch to LEDs instead. LEDs are getting popular day by day and hence you need to use them for your lighting industry. Some of the most common Murphy LED lights in the industrial market include street lights, high bay lights, and flood lights.

Murphy LED High Bay Lights

Murphy LED Flood Lights

Murphy LED Street Lights

In the commercial space, HIDs (High Intensity Discharge) are used when a large amount of light is needed to illuminate a sizeable area. To understand this, we need to talk about the HIDs and LEDs.

HIDs vs LEDs

HIDs are gas-discharge arc lamps that produce light by transmitting electrical current between two electrodes and ionized gas. There are several kinds of HIDs like: sodium, mercury, and metal halide termed as HPSV, HPMV, and HPMH.

LEDs, on the other hand, create light by exciting the electrons which then emit photons and lead to illumination. Although everything has its own pros and cons, there are several ways in which LEDs are superior than HIDs.

To understand, which category is more beneficial, let’s go through a detailed comparison with the help of a table.

Murphy LED Bulbs

| Aspect | HIDs | LEDs |

|---|---|---|

| Durability | These are relatively fragile and can break easily. | These are shock and vibration resistant. |

| Lifespan | 15,000 to 25,000 hours | 50,000- 1,00,000 hours |

| Cost | HIDs can be availed at low costs but are expensive to maintain. | LEDs have high initial costs but carry a low lifetime cost. |

| Maintenance | Require regular relamping and ballast replacement. | No maintenance expenses. |

| Efficiency | HIDs lose out when compared to LEDs as their efficiency is less than 30 lumens per watt. | LEDs are highly efficient and most values go beyond 150 lumens/watt. |

Color wavelength comparison between LED and High Pressure Sodium lights

1. Lamp (Source) Efficiency Vs Fixture (System) Efficiency

The light source is the component that produces light. It may operate simply as a lamp or it may be powered by a ballast or a driver. Moving on, the fixture is a complete unit that contains light source along with the components that diffuse light, components that protect and position the lamp, and connection to the power source.

The source efficiency of any light is measured by taking into account a bare lamp at room temperature. On the other hand, system efficiency is based on how many lumens are emitted from the lamp and reach the target area.

For HIDs, the source efficiency is 120 lumens/watt or more while the system efficiency is measured at 30 lumens/watt or less due to problems like unfavorable operating temperature or inefficient ballasts.

Coming to LEDs, the source efficiency is measure at 100 lumens/watt or more while the system efficiency is above 50 lumens/watt or more (including the efficiency of the drivers and the operating temperature).

2. Operating Life

Usually an HID bulb has a lifespan of 10,000 to 25,000 hours but LEDs offer extremely good longevity of up to 50,000 hours. In fact, many new LEDs can even last up to 1,00,000 hours or so.

Hours of operation comparison between metal halide and LED through graphical representation

3. Efficiency

An HID consumes much more energy than an LED to give the same light output

LEDs are the most efficient kind of lights as compared to the other categories as they need less power to perform. These luminaries consume very little energy but at the same time render a good amount of brightness.

When compared to HIDs, LEDs may perform for up to 150 lumens per watt while the former ones carry the efficiency of not more than 30 lumens per watt.

4. Pay Back Period

HIDs incur much more cost as compared to the LEDs

HIDs can be availed in half the cost incurred by LEDs but at the same time these high intensity discharge lamps require maintenance charges. On the other hand, you may have to pay more for the LEDs but then you won’t need to maintain them and there are no additional costs involved so you will get a more beneficial deal with them.

5. Quality of Light

The Light Distribution differs in case of Metal Halide and LED lights

A comparison of High Pressure Sodium Lights and LED lights on the street

HIDs when compared to LEDs are more mature in the market as they have been around for more than 2 decades. But when it comes to visibility, LEDs are the clear winner. Moreover, HIDs have a warm-up period of about 5 seconds while LEDs give instant brightness and hence more clarity as well as visibility.

Conclusion

LEDs are gradually putting HIDs out of business as these have a huge potential to bring a change in the lighting industry. One of the main reasons being the cost factor.

Other than that, LEDs have a greater system as well as source efficiency. Clearly people are making a better and informed decision and trends suggest that you should too.